Lewistown WWTP Improvements

Location Lewistown, MD

Client Frederick County Division of Utilities and Solid Waste, Dept. of Engineering and Planning

Size 27,000 GPD

Costs $2,195,000

Date of Completion 2021

Services #Architecture #Construction Services #Consulting #Structural Engineering #Water / Wastewater Engineering

Task: Lewistown WWTP Improvements Study

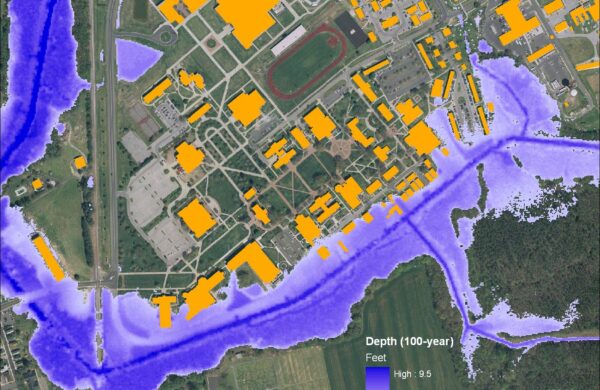

Frederick County Division of Utilities and Solid Waste Management (DUSWM) owns and operates the wastewater treatment facility at Lewistown Elementary School (ES) in Lewistown, Maryland. The treatment facility consists of an 8,000-gallon septic tank, pumping station, and underground sand filter that were installed in the early 1960’s. Ultraviolet disinfection equipment was added in the mid-1970’s. In 2013, a sanitary survey conducted by the Frederick County Health Department identified various public health issues due to problems with on-site sewage disposal systems (i.e., septic tanks). In October 2016, Maryland Department of the Environment (MDE) approved a Frederick County Water and Sewer Plan Amendment to establish a new sewer service area in Lewistown that would address the public health issues.

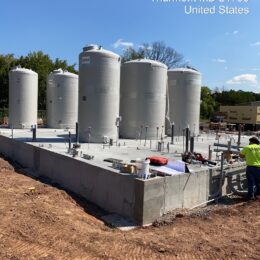

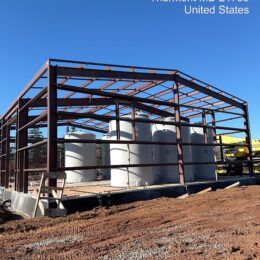

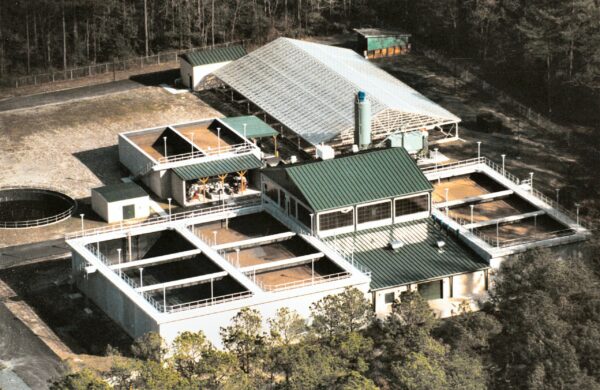

In 2017, Frederick County DUSWM retained George, Miles & Buhr, LLC (GMB) to develop treatment options for replacing the existing treatment facility at Lewistown ES with a new state-of-the-art wastewater treatment plant (WWTP). The new WWTP will include advanced Micro-Bio-Reactor (MBR) treatment technology designed in accordance with Maryland’s guidelines for Enhanced Nutrient Removal (ENR). GMB analyzed three (3) treatment options capable of producing high-quality effluent suitable for direct discharge to nearby Fishing Creek. GMB recommends replacing the existing septic tank and sand filter with a the mini-MBRTM manufactured by Innovative Treatment Products, LLC (ITP). The new MBR treatment process will be housed in a new wastewater treatment building located behind the elementary school. Other treatment plant upgrades will include a new flow equalization tank, mechanical screens, chemical storage and feed equipment, new electrical service, automated process controls and alarm system, new UV disinfection equipment, new sludge storage tank, post-aeration facilities, effluent flow meter, and emergency generator. Construction costs for the proposed treatment plant upgrade are estimated at $2,195,000 with annual operating costs estimated at $291,000 per year.